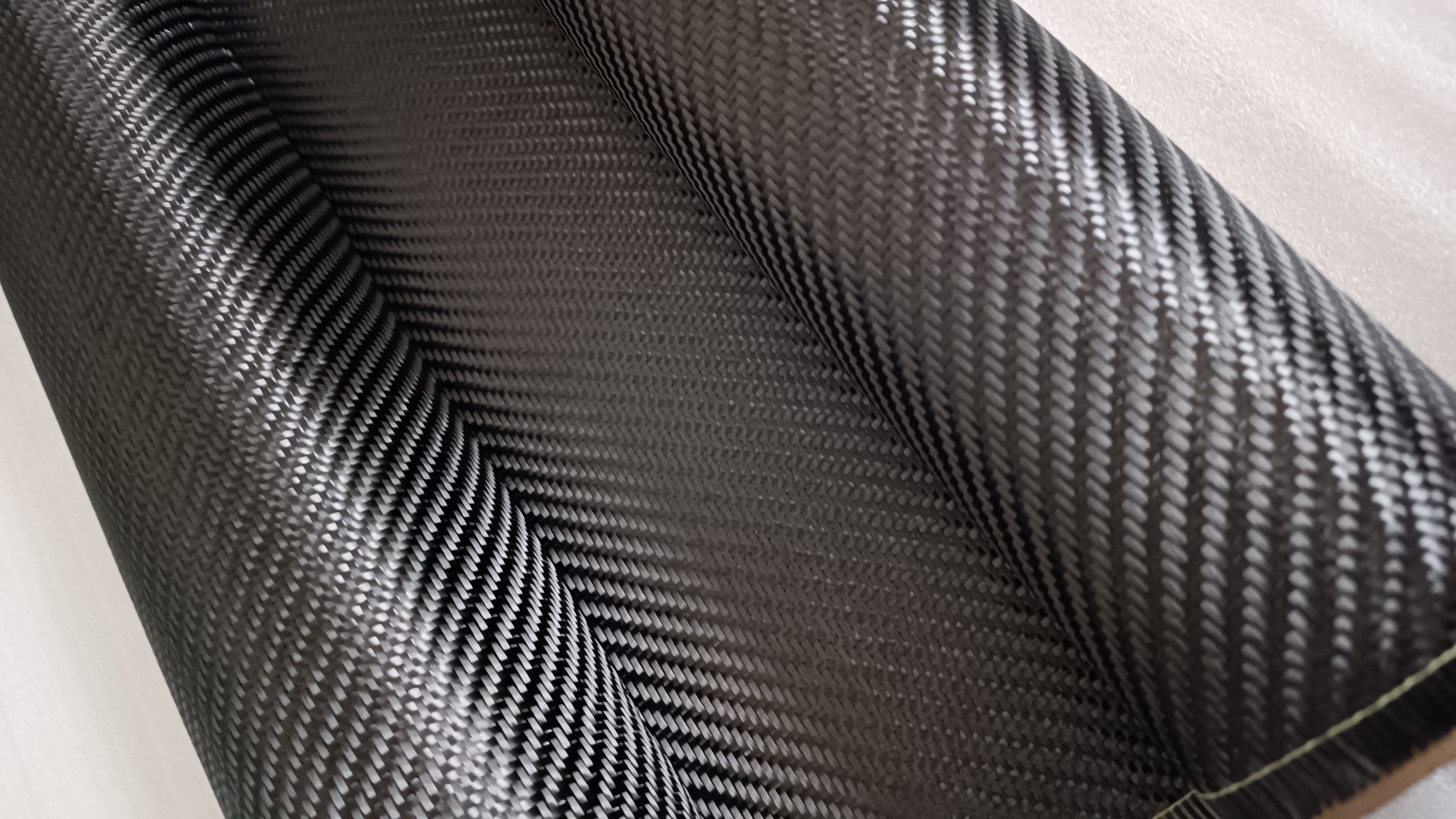

The use of carbon fabric in the marine manufacturing sector has revolutionized how vessels are constructed, contributing significantly to advancements in strength, durability, and overall performance. Carbon fabric, known for its exceptional strength-to-weight ratio, has become a material of choice for many manufacturers seeking to enhance the efficiency and longevity of their maritime products. This article delves into the various applications of carbon fabric within the marine industry, highlighting its benefits and the transformative impact it has had on marine manufacturing.

The Advantages of Carbon Fabric in Marine Construction

Carbon fabric stands out in marine manufacturing for several reasons. Firstly, its unparalleled strength and lightweight nature make it ideal for crafting vessels that are both robust and agile. The reduction in weight allows for greater fuel efficiency and higher speeds, which is particularly beneficial for racing yachts and high-speed powerboats. Furthermore, carbon fabric exhibits excellent resistance to corrosion caused by saltwater, making it a durable option for marine environments. Its adaptability to complex shapes also allows for innovative designs in yacht and boat construction, opening up new possibilities for aesthetics and functionality in marine vessels.

Innovative Applications of Carbon Fabric in Boatbuilding

One of the most notable applications of carbon fabric in the marine sector is in the construction of high-performance racing yachts. The material's ability to withstand immense stress while maintaining a light frame makes it indispensable for competitive sailing where every ounce matters. Additionally, luxury yacht manufacturers incorporate carbon fabric to achieve sleek, sturdy designs that offer superior comfort and performance. Beyond leisure and sport, carbon fabric is also utilized in the construction of commercial vessels and naval ships, where its strength and durability contribute to enhanced safety and longevity.

Enhancing Sustainability in Marine Manufacturing with Carbon Fabric

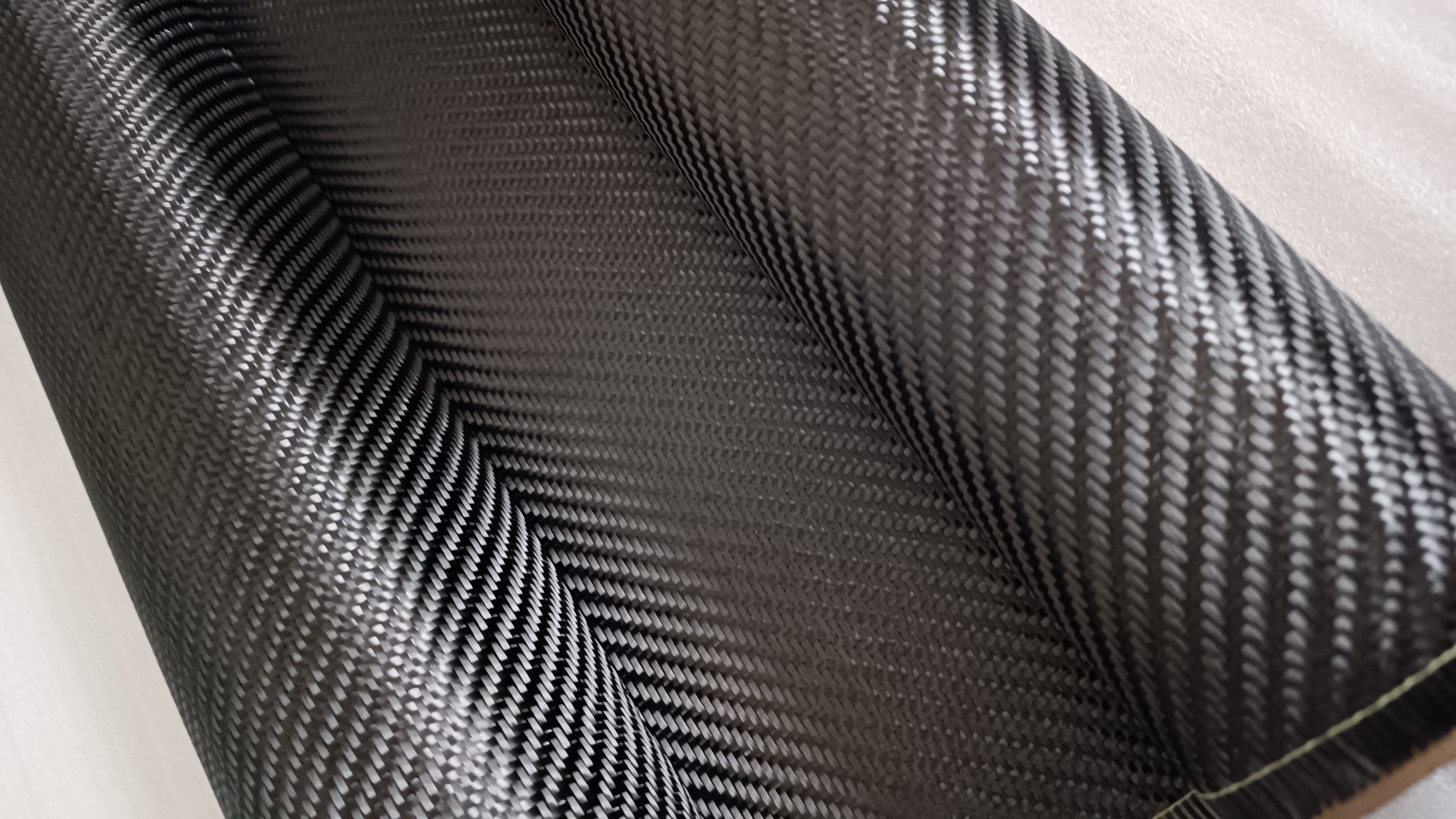

As the marine industry moves towards more sustainable practices, carbon fabric presents an environmentally friendly alternative to traditional materials like steel and aluminum. Its longer lifespan reduces the need for frequent replacements or repairs, contributing to lower lifecycle emissions. Moreover, the lightweight nature of carbon fabric leads to less fuel consumption and, consequently, reduced greenhouse gas emissions. By adopting carbon fabric, the marine manufacturing industry takes a significant step forward in minimizing its environmental footprint.

Challenges and Future Perspectives

Despite its numerous advantages, the adoption of carbon fabric in marine manufacturing faces challenges, primarily relating to cost and production complexities. Carbon fabric can be more expensive than traditional materials, which may limit its use to high-end or specialized vessels. However, as manufacturing techniques evolve and become more efficient, it is anticipated that the cost of carbon fabric will decrease, making it more accessible for a wider range of applications. The ongoing research into improving the properties of carbon fabric promises even greater advancements in marine manufacturing, potentially leading to a new era of innovative, efficient, and sustainable vessels.

In conclusion, carbon fabric has already made a significant impact on marine manufacturing, offering improvements in performance, durability, and sustainability. As the industry continues to evolve, the role of carbon fabric is expected to expand further, paving the way for more advanced and environmentally friendly maritime vessels. The future of marine manufacturing looks promising, with carbon fabric at the helm of innovation.