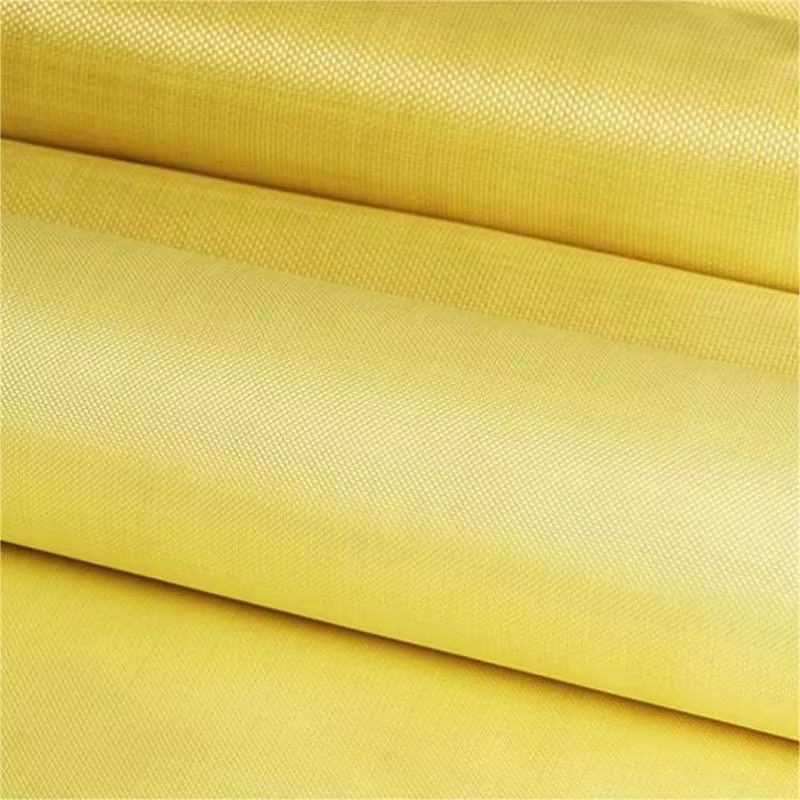

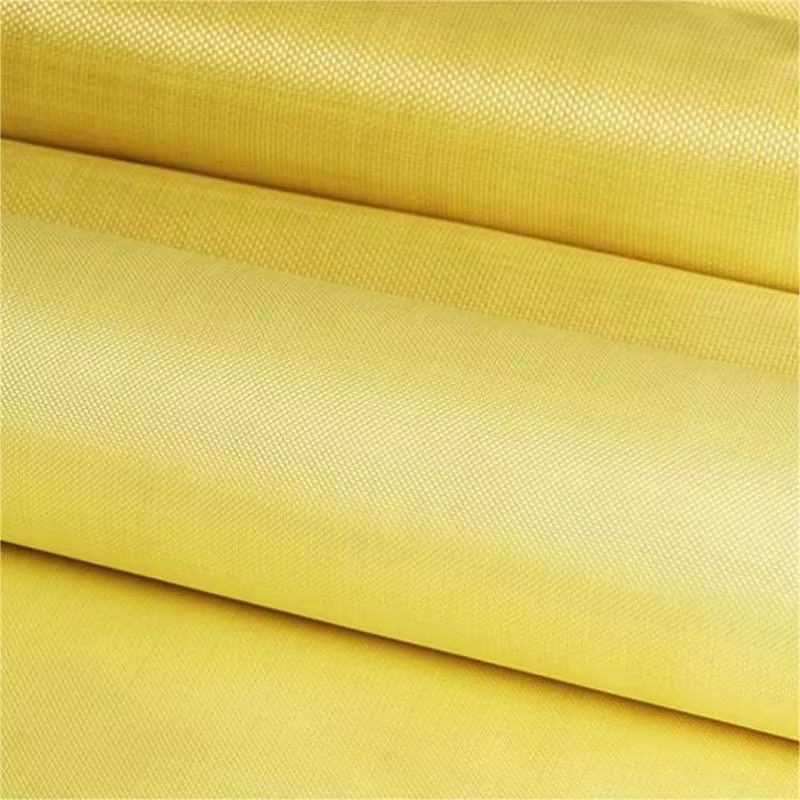

Aramid fabrics, renowned for their exceptional mechanical properties, have become a focal point in the realm of reinforced composites. With applications spanning aerospace to automotive industries, their integration into composite materials has been pivotal in advancing the performance and durability of these composites. In this comprehensive analysis, we delve into the mechanical strength of aramid fabric-reinforced composites, exploring their tensile, flexural, and impact resistance properties. This article aims to provide a detailed understanding of how aramid fibers enhance the mechanical strength of composites, supported by extensive experimental data and analysis.

Introduction

Aramid fibers, particularly Kevlar and Twaron, are synthetic fibers known for their high strength-to-weight ratio, low flammability, and high chemical resistance. These fibers are extensively used in aerospace, military, and automotive applications due to their superior mechanical properties. When integrated into composite materials, aramid fibers significantly enhance the mechanical strength, toughness, and impact resistance of the composites. This makes them an ideal choice for applications requiring high-performance materials that can withstand extreme conditions.

Experimental Section

In this section, we detail the methodology used to analyze the mechanical strength of aramid fabric-reinforced composites. This includes the selection of materials, preparation of composite samples, and the mechanical testing procedures employed to evaluate tensile strength, flexural strength, and impact resistance. The experimental setup is designed to ensure accurate and reproducible results, providing a clear understanding of the mechanical performance of aramid-reinforced composites.

Materials and methods

The study utilizes aramid fabrics, specifically Kevlar and Twaron, known for their high tensile strength and durability. These fabrics are integrated into epoxy resin matrices to form the composites. The preparation of the composite materials involves aligning the aramid fabrics in a specific orientation to maximize their load-bearing capacity. The epoxy resin is then cured under controlled conditions to ensure optimal bonding between the fibers and the matrix. Mechanical testing is conducted using standardized methods to evaluate the tensile, flexural, and impact properties of the composites.

Mechanical testing methods

The mechanical testing involves several standardized procedures. Tensile strength is measured using a universal testing machine, where the composite samples are subjected to a uniaxial load until failure. Flexural strength is evaluated using a three-point bending test, where the samples are loaded at their midpoint until they fracture. Impact resistance is assessed using an Izod impact test, where a notched sample is struck by a pendulum to measure the energy absorbed during fracture. These tests provide a comprehensive understanding of the mechanical strength and durability of aramid fabric-reinforced composites.

Results

The results of the mechanical strength analysis reveal significant enhancements in the tensile, flexural, and impact properties of aramid fabric-reinforced composites compared to unreinforced epoxy resins. The tensile strength of the composites is substantially higher, indicating better load-bearing capacity. The flexural strength, which measures the ability of the material to withstand bending forces, is also significantly improved. Additionally, the impact resistance, a critical property for applications exposed to sudden forces or shocks, shows a remarkable increase. These results demonstrate the effectiveness of aramid fibers in enhancing the mechanical strength and durability of epoxy resin composites.

Tensile strength

The tensile strength of aramid fabric-reinforced composites is significantly higher than that of unreinforced epoxy resins. The incorporation of aramid fibers enhances the load-bearing capacity of the composites, making them suitable for applications that require high strength and durability. The tensile strength is measured by subjecting the composite samples to a uniaxial load until failure. The results show that the composites can withstand higher loads without breaking, indicating their superior mechanical performance.

Flexural strength

The flexural strength of the composites, which measures their ability to resist deformation under load, is significantly enhanced by the incorporation of aramid fibers. The three-point bending test reveals that the composites can withstand higher bending forces without cracking or breaking. This improvement in flexural strength is attributed to the high tensile strength of aramid fibers, which provides better resistance to bending and flexural loads.

Impact resistance

The impact resistance of aramid fabric-reinforced composites shows a remarkable improvement compared to unreinforced epoxy resins. The Izod impact test indicates that the composites can absorb more energy upon impact, demonstrating their ability to withstand sudden forces or shocks without fracturing. This enhanced impact resistance is crucial for applications where materials are subjected to dynamic loads or harsh environmental conditions.

Discussion

The analysis of mechanical strength in aramid fabric-reinforced composites provides valuable insights into the performance and application potential of these materials. The significant improvements in tensile, flexural, and impact properties highlight the effectiveness of aramid fibers in enhancing the mechanical strength and durability of composites. These findings are consistent with previous studies, which have also reported the superior mechanical properties of aramid-reinforced composites. The high tensile strength, improved flexural strength, and enhanced impact resistance make aramid fabric-reinforced composites suitable for a wide range of applications, including aerospace, automotive, and protective gear.

The superior mechanical properties of aramid fabric-reinforced composites can be attributed to the unique structure and properties of aramid fibers. Aramid fibers have a high degree of crystallinity and molecular orientation, which imparts high tensile strength and rigidity. The strong covalent bonds between the polymer chains in aramid fibers contribute to their high strength and thermal stability. Additionally, the flexibility of aramid fibers allows them to absorb and dissipate energy, enhancing the impact resistance of the composites.

The integration of aramid fibers into epoxy resin matrices creates a synergistic effect, combining the high strength and flexibility of aramid fibers with the excellent adhesion and chemical resistance of epoxy resins. This combination results in composites with superior mechanical properties, making them suitable for applications requiring high strength, durability, and resistance to harsh environmental conditions.

Conclusion

The mechanical strength analysis of aramid fabric-reinforced composites demonstrates significant enhancements in tensile, flexural, and impact properties compared to unreinforced epoxy resins. The high tensile strength, improved flexural strength, and enhanced impact resistance of these composites make them suitable for a wide range of applications, including aerospace, automotive, and protective gear. The unique structure and properties of aramid fibers, combined with the excellent adhesion and chemical resistance of epoxy resins, contribute to the superior mechanical performance of these composites. Future research should focus on optimizing the fiber-matrix interface and exploring the potential of aramid fabric-reinforced composites in various industrial applications.