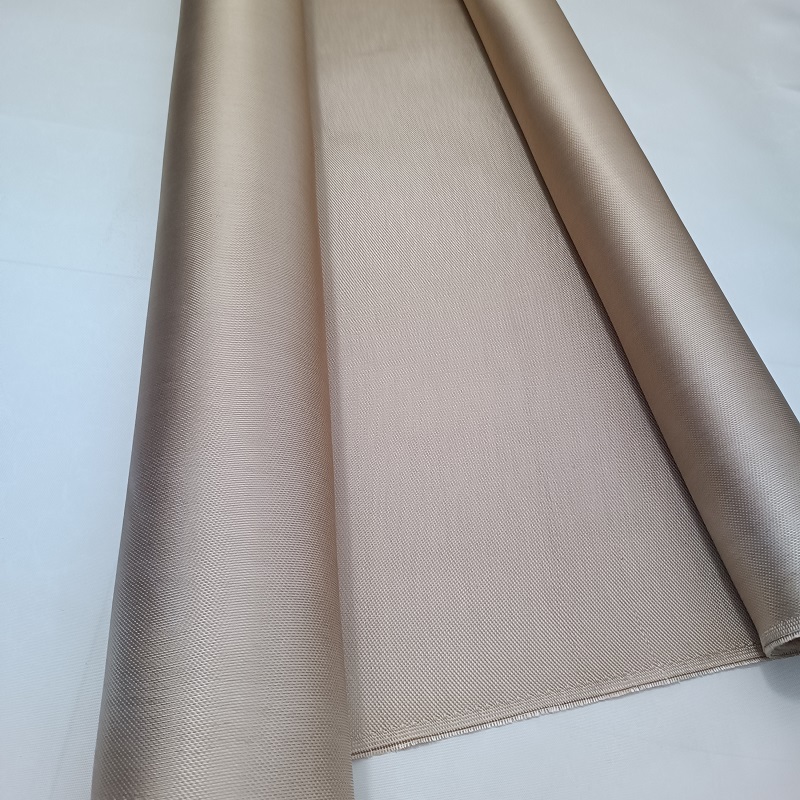

High silica fabric is a type of textile material made from high-purity silica fibers. Typically, the silica content in this fabric exceeds 96%, which gives it the ability to endure high temperatures—often beyond 1,000°C (1,832°F). This high silica composition grants the material exceptional thermal, fire, and chemical resistance, making it suitable for use in a range of demanding industrial and commercial applications.

Characteristics of High Silica Fabric

One of the defining features of high silica fabric is its resilience in extreme conditions. Due to its composition, the fabric boasts a variety of characteristics that make it ideal for specific uses:

Heat Resistance: High silica fabric can withstand continuous exposure to temperatures as high as 1,000°C without degrading or losing its integrity. This makes it a superior heat-resistant fabric compared to alternatives like fiberglass.

Fire Resistance: With its high melting point and low thermal conductivity, high silica fabric acts as an excellent fire-resistant barrier. It prevents heat transfer and minimizes the risk of fire spread.

Chemical Stability: High silica fabric is chemically inert, which means it does not react with most chemicals. This property adds another layer of protection, especially in environments where exposure to corrosive substances is a risk.

The Manufacturing Process of High Silica Fabric

The production of high silica fabric involves converting regular glass fibers into a higher silica content material. The process typically begins with the leaching of glass fibers, where they are treated to remove impurities and non-silica components. This results in a fabric that consists of more than 96% pure silica, which significantly enhances its heat and fire resistance capabilities.

Leaching Process in Detail

During the leaching process, glass fibers are treated with an acid solution that removes other mineral components, leaving behind almost pure silica. This step is crucial in creating the thermal and fire-resistant properties that high silica fabric is known for. The treated fibers are then woven into fabric using specialized looms, ensuring the material retains its mechanical strength while enhancing its durability against high heat.

Applications of High Silica Fabric

Given its exceptional properties, high silica fabric is used in a wide array of industries. Below are some of the primary applications of this versatile material:

Aerospace Industry

In the aerospace sector, high silica fabric is used to create thermal insulation systems that protect aircraft components from extreme temperatures. It’s also employed in the manufacturing of space suits, where astronauts are exposed to both extreme cold and heat.

Fire Protection

One of the most common uses of high silica fabric is in fire protection gear. Due to its fire-resistant qualities, the fabric is used in firefighting suits, fire blankets, and industrial heat shields. Fire-resistant high silica fabric is also integrated into protective curtains and barriers that prevent the spread of flames in hazardous environments.

Industrial Applications

In industries such as metallurgy and foundries, high silica fabric is used for thermal insulation in furnaces, kilns, and other high-temperature equipment. The heat-resistant high silica fabric acts as a barrier, preventing heat from escaping and protecting workers from burns or heat exposure.

Welding and Metal Cutting

High silica fabric is widely used as welding blankets, curtains, and screens to protect workers and equipment from the heat and sparks generated during metal cutting and welding processes. The thermal high silica fabric can easily endure the intense heat produced in these environments, offering superior protection.

Thermal High Silica Fabric – A Solution for Extreme Temperatures

Thermal high silica fabric is specifically designed to provide insulation in environments with high-temperature exposure. The ability of this fabric to resist heat without compromising its strength makes it indispensable in industries such as power generation, chemical processing, and automotive manufacturing.

Insulation for Power Plants

In power plants, particularly those using coal or nuclear fuel, heat-resistant high silica fabric is used for thermal insulation. It ensures that machinery and equipment maintain their operational efficiency by minimizing heat loss and safeguarding against heat damage.

Automotive Industry

Within the automotive industry, thermal high silica fabric plays a vital role in protecting components like exhaust systems, engine parts, and turbochargers from extreme heat. By doing so, it helps prevent overheating and extends the life of automotive parts.

Fire Resistant High Silica Fabric – An Essential for Safety

Fire resistant high silica fabric is invaluable in environments where fire hazards are a significant concern. Its ability to resist ignition and withstand direct exposure to flames makes it a critical component in personal protective equipment (PPE), safety barriers, and fire suppression systems.

Fire Blankets and Safety Gear

Fire-resistant high silica fabric is commonly used in fire blankets, which are deployed to smother small fires. Its non-combustible nature prevents the fabric from catching fire, ensuring it can be safely used to protect people and property from flames.

Fire Resistant Curtains

High silica fabric is often used to manufacture fire curtains in public spaces like theaters, factories, and storage facilities. These curtains serve as a critical safety feature, providing a barrier to prevent fire from spreading rapidly.

Heat-Resistant High Silica Fabric – Tackling Extreme Heat

When it comes to handling extreme heat, few materials are as effective as heat-resistant high silica fabric. This fabric is specially designed to maintain its structure and performance even when exposed to temperatures exceeding 1,000°C.

Foundry Applications

In foundries, where molten metals are handled regularly, heat-resistant high silica fabric is often used to create protective clothing and insulation materials. Workers are shielded from extreme heat and splashes of molten metal, ensuring their safety during high-risk operations.

Furnace Insulation

High-temperature furnaces, whether used in metal smelting, glass production, or ceramics manufacturing, require efficient insulation to operate safely. Heat-resistant high silica fabric provides this insulation by minimizing heat loss and protecting the furnace's structure from degradation over time.

Advantages of High Silica Fabric

There are several advantages to using high silica fabric over other heat-resistant materials:

Superior Heat Resistance: Withstanding temperatures well over 1,000°C, high silica fabric outperforms other materials like asbestos and fiberglass.

Durability: High silica fabric is extremely durable, maintaining its structure and function over prolonged periods, even in harsh environments.

Non-Toxic and Safe: Unlike asbestos, high silica fabric is non-toxic and safe for human handling, making it an environmentally friendly choice for industrial applications.

Comparing High Silica Fabric to Other Materials

While fiberglass and ceramic fabrics are commonly used in similar applications, high silica fabric offers enhanced performance in extreme environments. Fiberglass has a lower temperature resistance, while ceramic materials can be more brittle. High silica fabric strikes a balance between flexibility, durability, and heat resistance, making it a superior choice in many scenarios.

Maintenance and Care of High Silica Fabric

To ensure the longevity of high silica fabric, it’s essential to follow proper care and maintenance practices. The fabric should be inspected regularly for wear and tear, especially in high-stress environments like industrial furnaces or welding areas. Proper storage, away from direct sunlight and chemical exposure, can also prolong the fabric's lifespan.

Conclusion

High silica fabric is a remarkable material, offering unparalleled heat and fire resistance in a wide range of industrial applications. Whether it’s for thermal insulation in power plants, fire protection in hazardous environments, or heat shielding in aerospace applications, this fabric is the go-to solution for extreme conditions. By understanding the unique properties of high silica fabric, industries can better utilize its potential to enhance safety, efficiency, and durability in their operations.