Fiberglass is often used in the construction of skis to enhance their strength, stiffness, and durability. The following are common applications of fiberglass on skis:

1. Board core reinforcement

Fiberglass can be embedded into the wood core of the ski to increase overall strength and stiffness. This application improves the responsiveness and stability of the ski.

2. Board bottom

Fiberglass is often coated on the bottom of skis to increase the base's wear resistance and gliding properties. This coating reduces friction and increases the speed of the ski on the snow.

3.Edge enhancement

Some skis may contain fiberglass reinforcements on their edges to increase the edge's impact and abrasion resistance. This helps protect edges and prolongs the life of the ski.

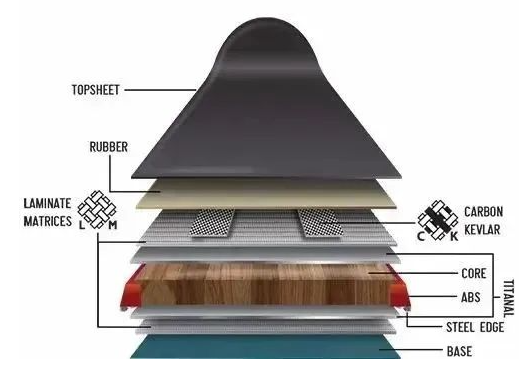

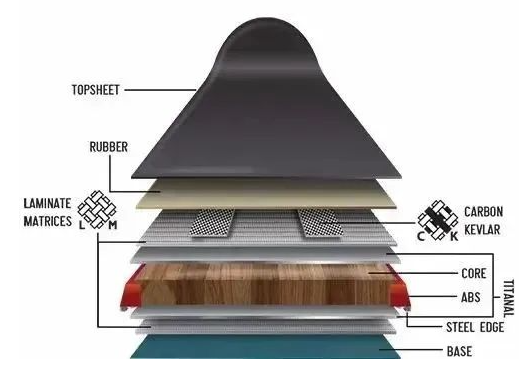

4.Composite layer

Fiberglass is often used along with other composite materials, such as carbon fiber, to form the different layers of a ski. This combination can tune the performance of the ski, making it lighter, stronger, more nimble, and more.

5.Binding system

Some skis may use fiberglass-reinforced plastic or composite materials in their binding systems to increase the stability and durability of the binding system.

The use of fiberglass helps make the ski lighter while adding strength to the overall structure. This provides better handling and longer life, allowing skiers to better adapt to a variety of snow conditions and terrain.

While fiberglass offers some advantages in ski manufacturing, there are also some disadvantages, especially when compared to some high-performance materials. For example, compared to some high-performance lightweight materials such as carbon fiber, glass fiber has a higher proportion. This can result in a relatively heavy overall ski weight, reducing handling and agility; although fiberglass has higher strength, its strength-to-weight ratio is relatively low and performs poorly compared to some other high-performance fiber materials. ; Glass fiber is relatively rigid, which may make the ski too rigid in some cases, reducing the flexibility of the board; compared with some high-performance fibers such as carbon fiber, glass fiber has relatively low impact resistance. Under extreme conditions, such as large impacts or bends, fiberglass may break; fiberglass may exhibit some temperature sensitivity under extreme temperatures, which may affect the performance of the ski in different snow conditions and temperatures.