PTFE-coated fiberglass fabric has become a go-to material in various industries due to its exceptional properties. With its high-temperature resistance, chemical inertness, and low friction coefficient, it’s no wonder that this fabric is widely used in insulation pads for various applications. In this article, we’ll explore the applications of PTFE-coated fiberglass fabric in insulation pads and why it’s the preferred choice for many industries.

Understanding PTFE-coated fiberglass fabric

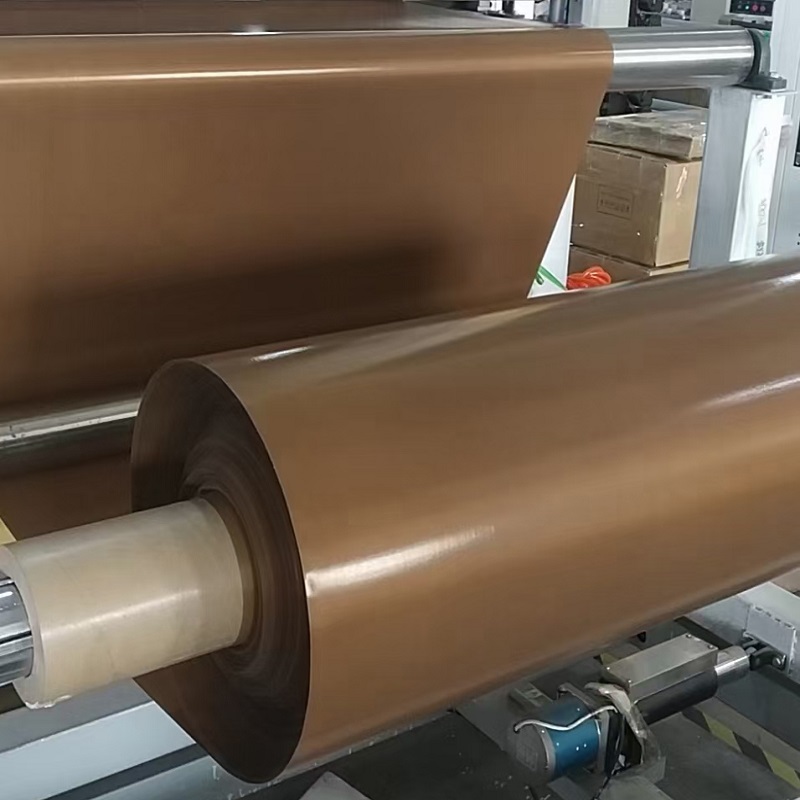

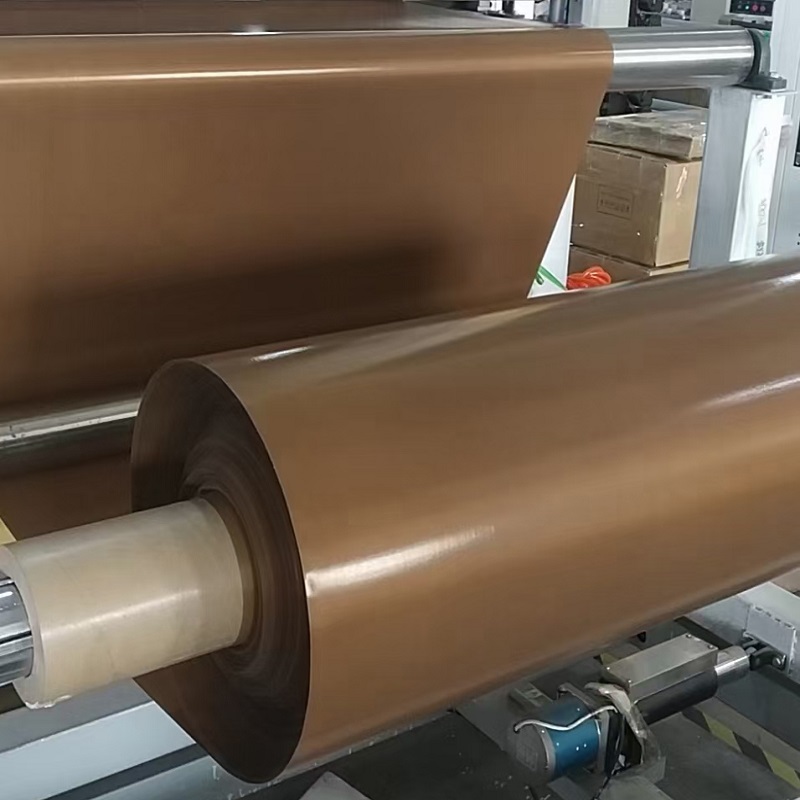

PTFE-coated fiberglass fabric is a high-performance material made by coating fiberglass fabric with polytetrafluoroethylene (PTFE). PTFE is a fluoropolymer known for its non-stick properties, high-temperature resistance, and chemical inertness. When combined with fiberglass, it creates a fabric that can withstand extreme temperatures and harsh environments.

PTFE-coated fiberglass fabric is available in various thicknesses and widths, making it suitable for different applications. It’s also easy to clean and maintain, making it a popular choice for insulation pads.

Applications of PTFE-coated fiberglass fabric in insulation pads

PTFE-coated fiberglass fabric has a wide range of applications in insulation pads. Here are some of the most common applications:

High-temperature insulation pads

PTFE-coated fiberglass fabric is ideal for high-temperature insulation pads used in industries such as aerospace, automotive, and manufacturing. Its high-temperature resistance allows it to withstand extreme temperatures without degrading or melting.

These insulation pads are used to protect sensitive equipment from heat damage and improve energy efficiency. They can be used in ovens, kilns, and other high-temperature applications.

Chemical-resistant insulation pads

PTFE-coated fiberglass fabric is also used in chemical-resistant insulation pads. Its chemical inertness makes it resistant to harsh chemicals, acids, and solvents. This makes it ideal for use in industries such as pharmaceuticals, food processing, and chemical manufacturing.

These insulation pads are used to protect equipment from chemical damage and improve safety. They can be used in tanks, pipes, and other applications where chemical resistance is required.

Low-friction insulation pads

PTFE-coated fiberglass fabric has a low friction coefficient, making it ideal for use in low-friction insulation pads. This type of insulation pad is used to reduce friction between moving parts and improve efficiency.

These insulation pads are used in various industries, including automotive, manufacturing, and construction. They can be used in bearings, gears, and other applications where low friction is required.

Benefits of using PTFE-coated fiberglass fabric in insulation pads

There are several benefits to using PTFE-coated fiberglass fabric in insulation pads:

High-temperature resistance

PTFE-coated fiberglass fabric can withstand extreme temperatures without degrading or melting. This makes it ideal for use in high-temperature applications such as ovens, kilns, and other heat-intensive environments.

Chemical inertness

PTFE-coated fiberglass fabric is resistant to harsh chemicals, acids, and solvents. This makes it ideal for use in chemical-resistant insulation pads used in industries such as pharmaceuticals, food processing, and chemical manufacturing.

Low friction

PTFE-coated fiberglass fabric has a low friction coefficient, making it ideal for use in low-friction insulation pads. This type of insulation pad is used to reduce friction between moving parts and improve efficiency.

Easy to clean and maintain

PTFE-coated fiberglass fabric is easy to clean and maintain, making it a popular choice for insulation pads. It can be cleaned with soap and water or other mild detergents.

Conclusion

PTFE-coated fiberglass fabric is a versatile and high-performance material used in various industries for insulation pads. Its exceptional properties, such as high-temperature resistance, chemical inertness, and low friction coefficient, make it a preferred choice for many applications.

Whether used in high-temperature, chemical-resistant, or low-friction insulation pads, PTFE-coated fiberglass fabric provides superior performance and durability. As industries continue to evolve, PTFE-coated fiberglass fabric will remain a go-to material for insulation pads.