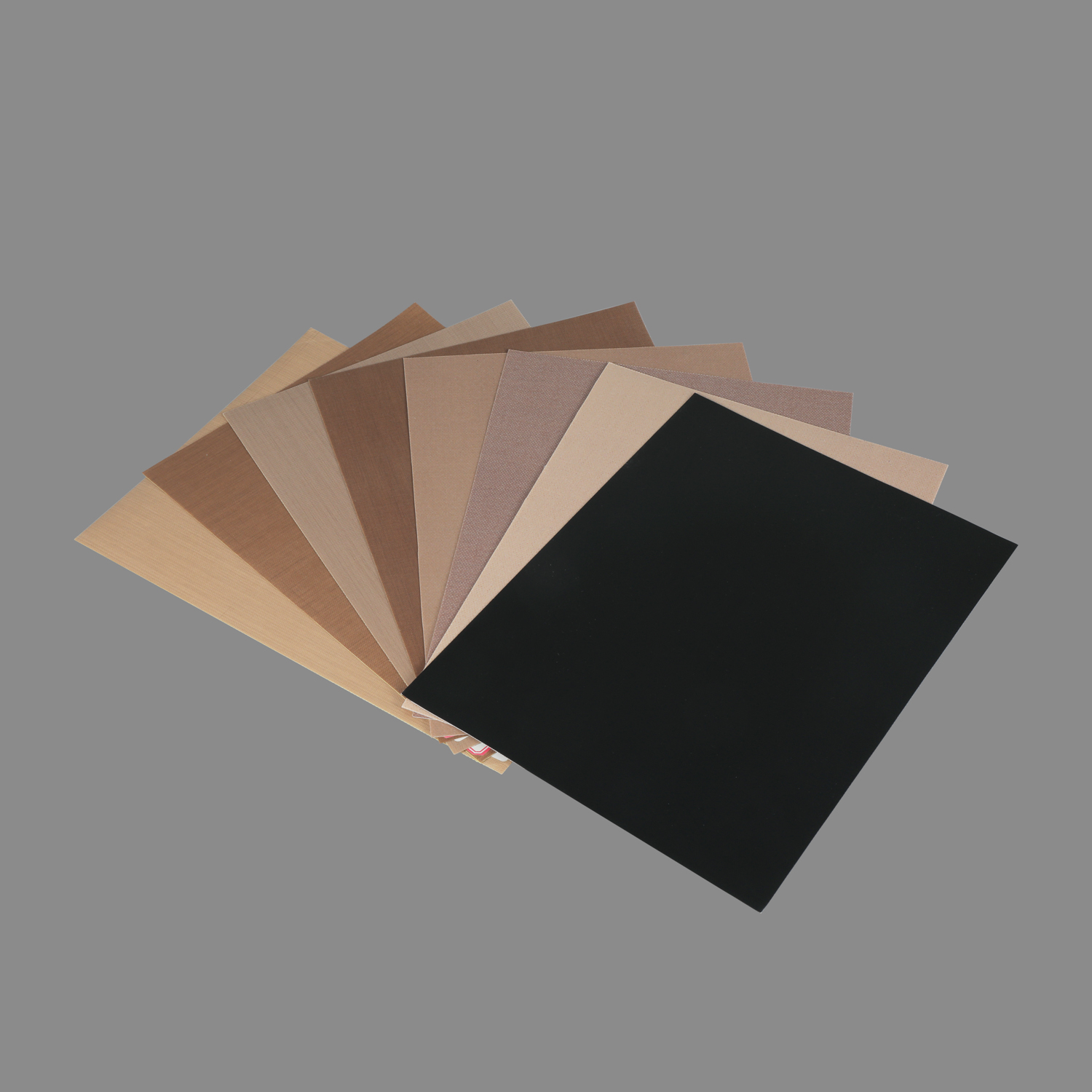

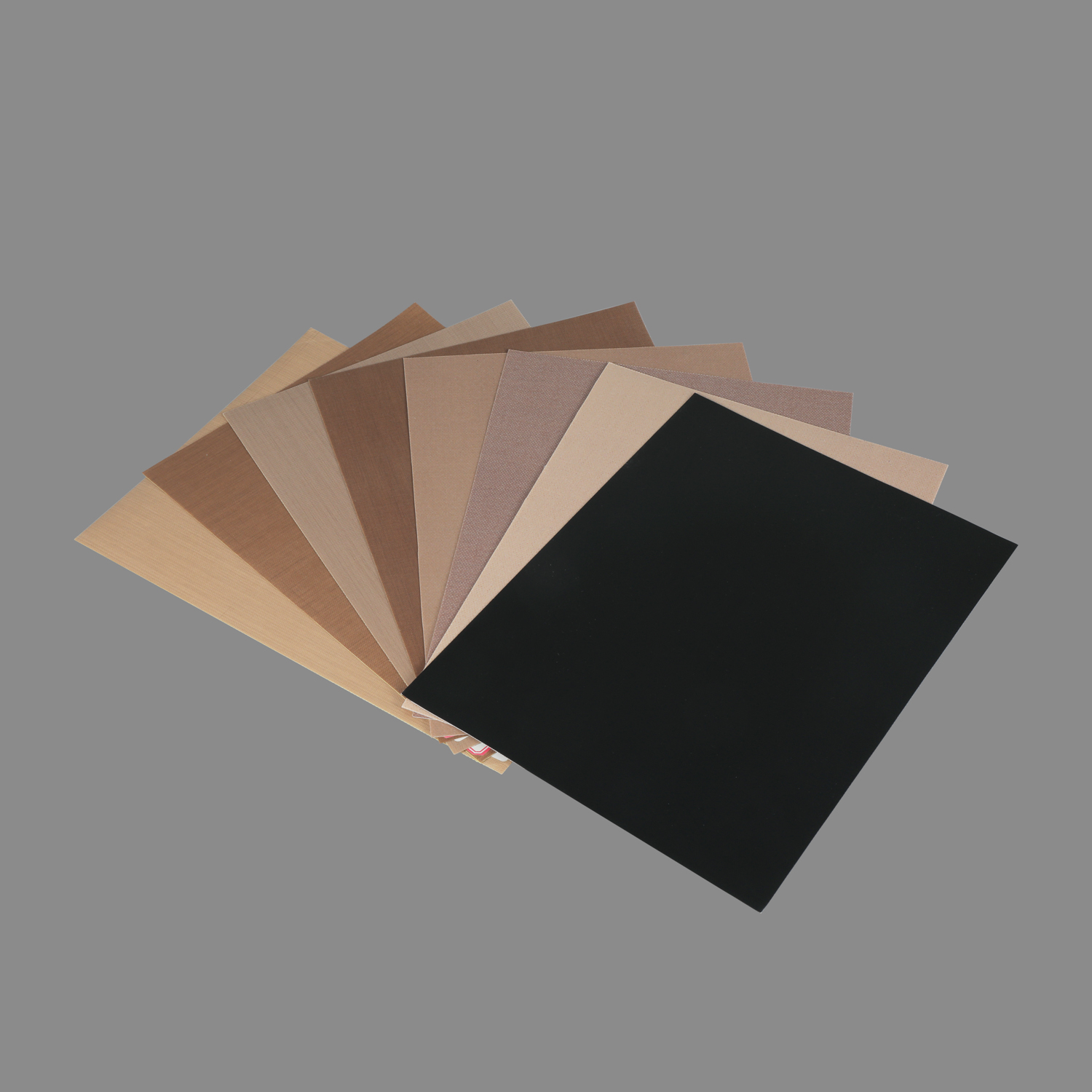

PTFE coated fiberglass fabric is a versatile material widely used in various industries, especially in high-temperature environments. Its unique properties make it an ideal choice for applications where traditional materials may fail. This article explores the durability of PTFE coated fiberglass fabric in high-temperature environments, focusing on its resistance to heat, chemical stability, and mechanical strength.

Learn more about PTFE coated fiberglass fabric

PTFE (Polytetrafluoroethylene) coated fiberglass fabric is a composite material made by combining fiberglass fabric with a PTFE coating. This combination results in a material that offers the best of both worlds: the strength and durability of fiberglass and the chemical resistance and low friction properties of PTFE.

Fiberglass fabric is known for its high tensile strength, low thermal expansion, and excellent electrical insulation properties. However, when exposed to high temperatures, fiberglass can become brittle and lose its structural integrity. This is where the PTFE coating comes into play. PTFE is a highly stable polymer that can withstand extreme temperatures without degrading or losing its properties.

The PTFE coating enhances the fiberglass fabric’s durability in high-temperature environments, making it suitable for various applications such as industrial conveyor belts, heat sealing machines, and high-temperature insulation.

Key properties contributing to durability

Several key properties of PTFE coated fiberglass fabric contribute to its durability in high-temperature environments:

High-temperature resistance

One of the most significant advantages of PTFE coated fiberglass fabric is its ability to withstand high temperatures. PTFE can withstand temperatures up to 500°F (260°C) without degrading or losing its properties. In contrast, fiberglass fabric can only withstand temperatures up to 1000°F (537°C).

The combination of these two materials results in a fabric that can withstand temperatures up to 1000°F (537°C) without losing its structural integrity. This makes it ideal for applications in high-temperature environments such as heat sealing machines, industrial ovens, and other applications where traditional materials may fail.

Chemical resistance

PTFE is highly resistant to chemicals, making it suitable for applications where it may come into contact with corrosive substances. It can withstand exposure to acids, bases, solvents, and other harsh chemicals without degrading or losing its properties.

This chemical resistance is essential in high-temperature environments where corrosive substances are often present. PTFE coated fiberglass fabric can be used in applications such as chemical processing, food processing, and pharmaceutical manufacturing, where traditional materials may fail due to chemical exposure.

Low friction coefficient

PTFE has a low friction coefficient, which means it can reduce friction and wear in applications where it is used as a liner or a bearing surface. This property is essential in high-temperature environments where traditional materials may wear out quickly due to friction.

By reducing friction and wear, PTFE coated fiberglass fabric can extend the life of equipment and reduce maintenance costs. This makes it ideal for applications such as conveyor belts, chutes, and other applications where friction and wear are a concern.

Mechanical strength

PTFE coated fiberglass fabric has excellent mechanical strength, which means it can withstand high tensile and compressive forces without breaking or deforming. This property is essential in high-temperature environments where materials are often subjected to extreme forces.

The combination of fiberglass and PTFE results in a material that can withstand high mechanical stress without losing its properties. This makes it ideal for applications such as industrial conveyor belts, heat sealing machines, and other applications where traditional materials may fail due to mechanical stress.

Applications of PTFE coated fiberglass fabric in high-temperature environments

PTFE coated fiberglass fabric is used in various industries and applications due to its durability and unique properties. Some of the most common applications include:

Industrial conveyor belts

PTFE coated fiberglass fabric is widely used in industrial conveyor belts due to its high-temperature resistance and low friction coefficient. It can withstand extreme temperatures and reduce friction, making it ideal for applications such as food processing, packaging, and material handling.

Heat sealing machines

Heat sealing machines require materials that can withstand high temperatures and provide a smooth, non-stick surface. PTFE coated fiberglass fabric meets these requirements, making it ideal for applications such as packaging, labeling, and sealing.

High-temperature insulation

PTFE coated fiberglass fabric is used as insulation in high-temperature environments due to its excellent thermal resistance and low thermal conductivity. It can be used in applications such as furnace linings, kiln wraps, and other high-temperature insulation applications.

Chemical processing

PTFE coated fiberglass fabric is highly resistant to chemicals, making it suitable for applications such as chemical processing, pharmaceutical manufacturing, and food processing. It can withstand exposure to acids, bases, solvents, and other harsh chemicals without degrading or losing its properties.

Electrical insulation

PTFE coated fiberglass fabric is an excellent electrical insulator due to its low thermal conductivity and high dielectric strength. It can be used in applications such as electrical insulation, wire coatings, and other electrical insulation applications in high-temperature environments.

Conclusion

In conclusion, PTFE coated fiberglass fabric is a highly durable material that can withstand high temperatures, chemicals, and mechanical stress. Its unique properties make it ideal for various applications in high-temperature environments, such as industrial conveyor belts, heat sealing machines, chemical processing, and electrical insulation. The combination of fiberglass and PTFE results in a material that offers the best of both worlds: the strength and durability of fiberglass and the chemical resistance and low friction properties of PTFE. PTFE coated fiberglass fabric is an excellent choice for applications where traditional materials may fail due to high temperatures, chemical exposure, or mechanical stress.