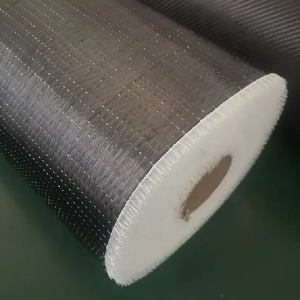

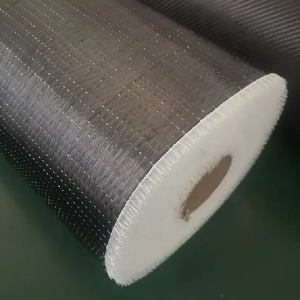

Carbon UD fabric, also known as unidirectional carbon fiber fabric, is one of the most advanced reinforcement materials in the composites industry. It is made by aligning carbon fibers in a single, parallel direction to achieve maximum strength along that axis. This design enables engineers to create structures that are lightweight yet extremely strong, making it a go-to solution for aerospace components, automotive parts, sporting equipment, and high-performance industrial applications. The exceptional mechanical properties, combined with resistance to environmental factors, place Carbon UD fabric among the top choices for projects where performance and reliability are critical.

Directional Strength Optimization

One of the defining characteristics of Carbon UD fabric is its exceptional directional strength. Unlike woven fabrics, where fibers are interlaced and distribute loads across multiple angles, UD fabric has all fibers running in a perfectly parallel alignment in the same direction. This unique arrangement enables it to deliver the highest possible tensile strength and stiffness along that specific fiber axis, without the compromises that come from crisscross patterns. Engineers can take advantage of this by strategically placing layers so that the fibers are oriented in the exact direction of the expected loads, ensuring maximum efficiency in weight-to-strength performance and minimizing wasted material capacity.

When compared to metals such as aluminum or steel, Carbon UD fabric can achieve comparable or even superior tensile strength while weighing only a fraction as much. This dramatic weight savings plays a critical role in industries where performance depends on minimizing mass. In aerospace applications such as wing spars and control surfaces, lighter structures directly translate into improved fuel efficiency and greater payload capacity. In high-performance automotive chassis reinforcements, reduced weight improves acceleration, handling, and braking. For bicycle frames and sporting equipment, the combination of low weight and high stiffness offers a competitive edge for athletes.

Another remarkable advantage is the ability to combine multiple UD layers at different angles within a single laminate. By doing so, designers can achieve multi-directional strength while still retaining the exceptional performance characteristics of each individual layer. This level of design flexibility allows Carbon UD fabric to be used in everything from precision-engineered aerospace components to everyday performance gear, making it an indispensable material for creating tailor-made mechanical properties in advanced composite structures.

Lightweight Design

Weight reduction is one of the primary reasons industries choose Carbon UD fabric over traditional materials. The exceptional strength-to-weight ratio allows engineers and designers to create components that are significantly lighter without any compromise in performance or safety. For example, replacing conventional steel with UD carbon composites in automotive body panels or structural reinforcements can achieve weight savings of up to 50–70%. This reduction not only improves acceleration and handling but also enhances fuel efficiency and lowers overall emissions, helping manufacturers meet increasingly strict environmental regulations.

In the aerospace sector, where every kilogram saved can result in measurable gains, weight directly impacts fuel consumption, operational range, and payload capacity. By integrating Carbon UD fabric into wing structures, fuselage sections, and control surfaces, aircraft can achieve substantial weight savings, which in turn can translate into millions of dollars in operational savings over the lifespan of the plane. Lighter components also contribute to improved climb rates and more efficient cruising speeds.

The benefits extend beyond heavy industry. In sporting goods, where performance is closely tied to agility and responsiveness, lighter products often give users a competitive edge. A tennis racket reinforced with Carbon UD fabric can enable faster swing speeds, while a bicycle frame made from the same material improves maneuverability and reduces rider fatigue. Additionally, lighter designs make manufacturing, transportation, and installation faster, safer, and more cost-effective, ensuring value at every stage of a product’s life cycle.

Customizable Performance

One of the greatest strengths of Carbon UD fabric is the ability to customize its performance through layer orientation and stacking sequences. By placing layers at different angles—such as 0°, 45°, and 90°—engineers can design a composite that handles complex, multi-directional loads while optimizing strength where it is needed most. This approach is especially useful in applications such as wind turbine blades, boat masts, and robotic arms, where forces may vary in direction and intensity.

The customization does not end with fiber orientation. Different grades of carbon fiber can be chosen to prioritize stiffness, strength, or impact resistance. Additionally, pairing UD fabric with specific resin systems—epoxy, vinyl ester, or polyester—can enhance properties like toughness, temperature resistance, or chemical stability. This adaptability allows for complete design freedom, making it possible to create a solution tailored to both the performance requirements and environmental conditions of the application.

Corrosion Resistance

Carbon UD fabric is inherently resistant to corrosion, which gives it a clear advantage over metals in environments where exposure to moisture, chemicals, or salt is unavoidable. Unlike steel, which can rust, or aluminum, which can suffer from pitting corrosion, carbon fibers do not degrade when exposed to water or oxygen. When encapsulated in a protective resin matrix, UD fabric becomes nearly impervious to many corrosive elements, including acids, alkalis, and salt spray.

This property makes it highly suitable for marine and offshore applications, such as ship hull reinforcements, dock components, and offshore oil platform structures. In chemical processing plants, where harsh substances are constantly present, Carbon UD fabric ensures structural integrity and reduces maintenance needs. This long-lasting corrosion resistance not only extends the service life of components but also significantly lowers lifecycle costs by minimizing repair and replacement requirements.

Thermal Stability

High thermal stability is another important advantage of Carbon UD fabric. It can maintain its mechanical properties even when exposed to elevated temperatures, making it suitable for applications where heat resistance is critical. Carbon fibers have a very low coefficient of thermal expansion, meaning they do not expand or contract significantly with temperature changes. This dimensional stability is essential for precision structures such as aerospace components, satellite parts, and high-speed machinery.

In motorsport applications, Carbon UD fabric is often used in brake systems, engine components, and aerodynamic parts that must endure high heat without losing performance. In industrial settings, it can be used in tooling and molds where repeated heating and cooling cycles occur. This stability not only enhances performance but also helps maintain accuracy in demanding environments where even minor dimensional changes could lead to failure.

Durability and Maintenance

The durability of Carbon UD fabric is one of the reasons it has become so popular in long-term, high-performance applications. Its resistance to fatigue, impact, and environmental degradation means that components can last for decades with minimal maintenance. Unlike metals that may require regular inspections for corrosion or cracks, UD carbon components maintain their integrity with less frequent upkeep.

For example, in infrastructure projects like bridges or architectural reinforcements, using Carbon UD fabric can greatly extend service life while reducing maintenance costs. In sports equipment, it ensures consistent performance season after season, even under intense use. The low maintenance requirement is a major advantage for industries aiming to reduce downtime and operational expenses.

Conclusion

Carbon UD fabric is a highly specialized composite reinforcement material that offers exceptional strength in a specific direction while maintaining a remarkably lightweight profile. With advantages such as directional strength optimization, customizable performance, corrosion resistance, thermal stability, and outstanding long-term durability, it has become a preferred choice in demanding fields like aerospace, automotive, marine, sports equipment, and industrial manufacturing. By precisely orienting UD layers, engineers can design structures that meet exact load requirements while ensuring maximum efficiency and performance.

As industries worldwide increasingly focus on solutions that balance high performance, low weight, and long service life, Carbon UD fabric continues to stand out as a cornerstone material in advanced composite engineering. Its proven ability to deliver both structural excellence and environmental resilience ensures it will remain vital in future lightweight, high-strength designs.

For companies seeking reliable, high-quality Carbon UD fabric solutions, Jiahe Taizhou Glass Fiber Co., Ltd. offers expertise, advanced manufacturing capabilities, and a strong commitment to customer satisfaction. With years of experience in composite reinforcement materials, they are well-positioned to provide tailored solutions for your projects. To learn more or discuss your specific requirements, you are encouraged to contact Jiahe Taizhou Glass Fiber Co., Ltd. directly for professional support.