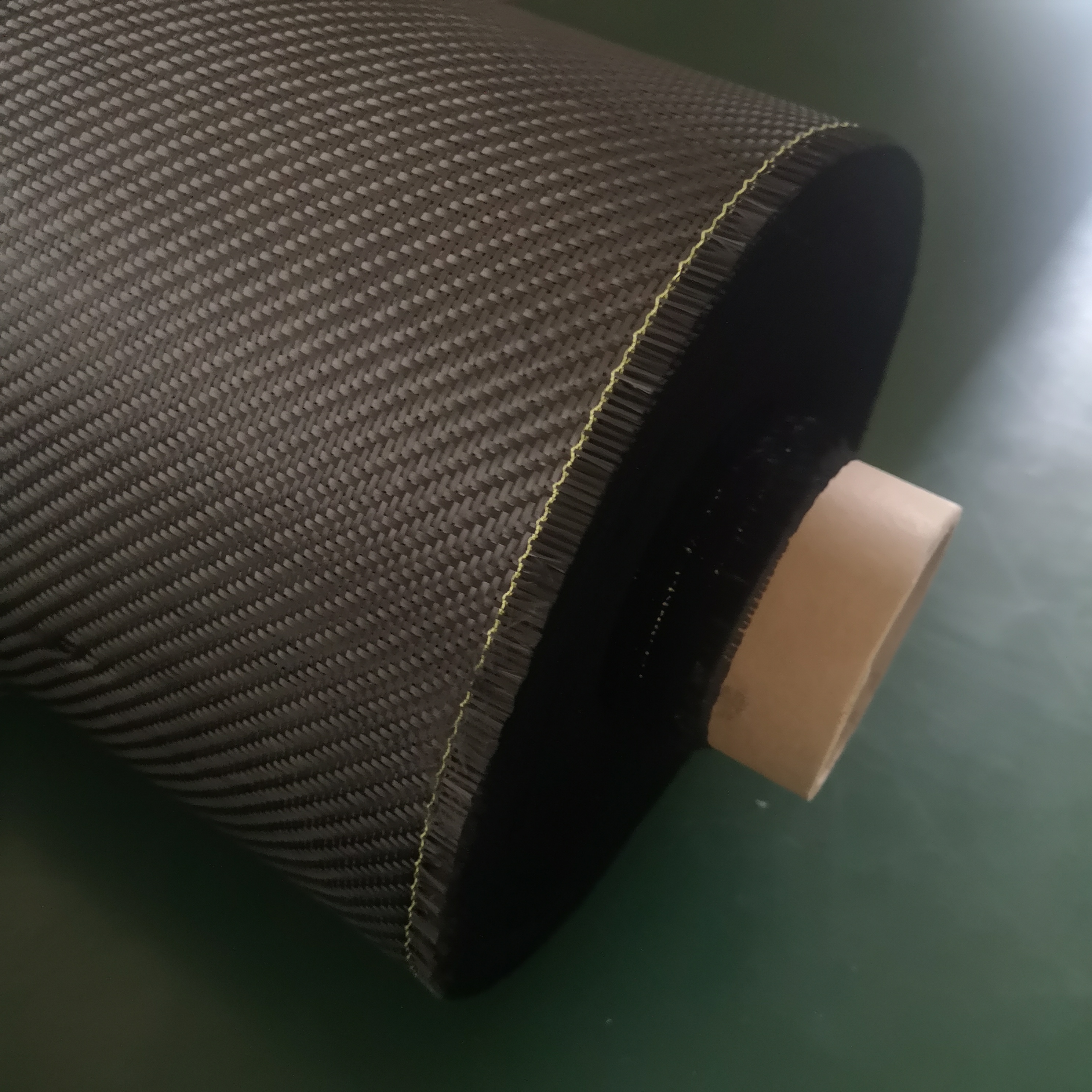

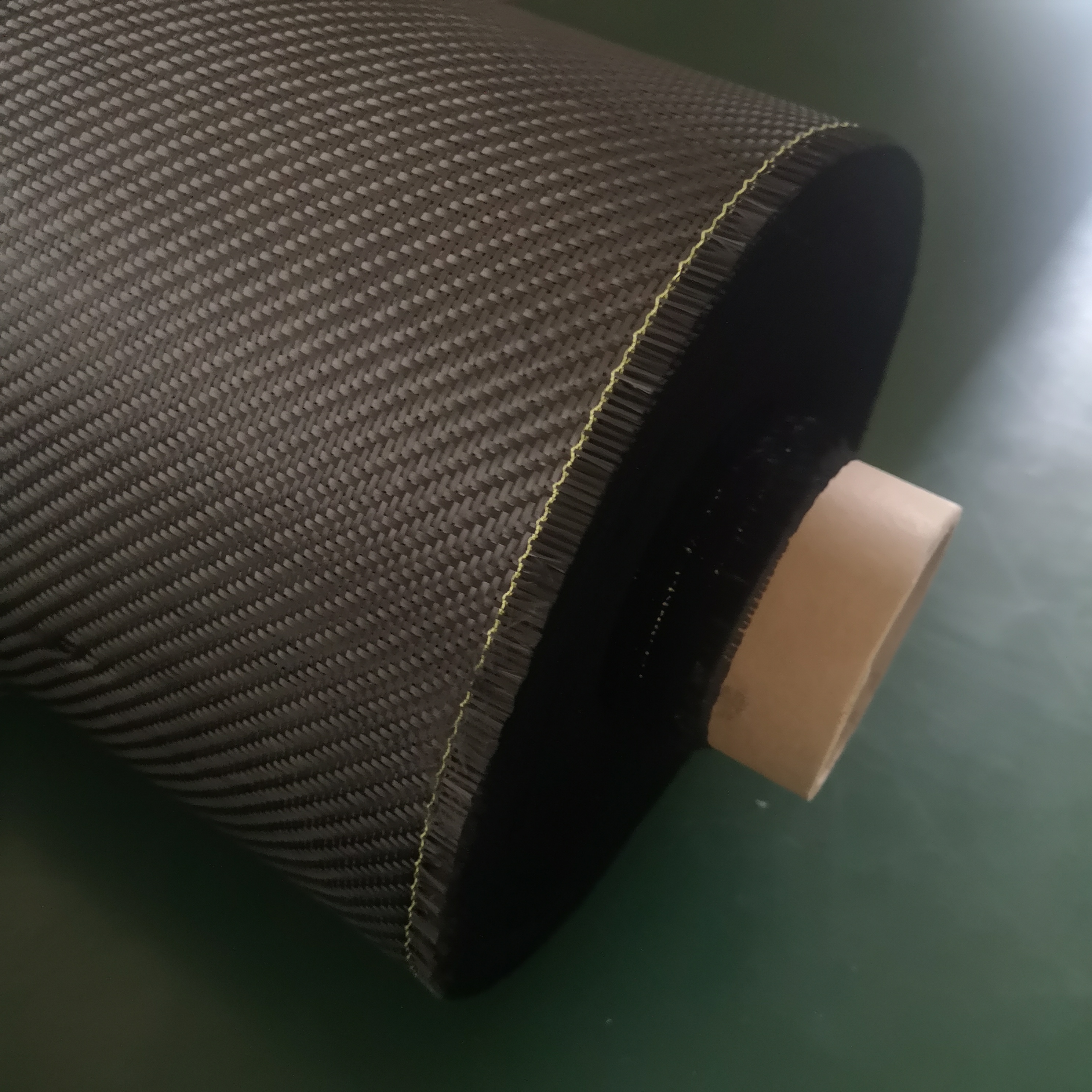

Selecting the right Carbon UD fabric is a critical step in ensuring the success of any composite material project, whether in aerospace, automotive, sporting goods, or structural reinforcement. Carbon UD fabric provides unmatched strength-to-weight performance, but improper selection can lead to inefficient designs, higher costs, or even material failure. Understanding the unique properties of unidirectional carbon fibers, the different resin systems, environmental requirements, and application-specific demands is essential for engineers and designers who aim to achieve optimal results. Choosing the correct fabric can affect the overall performance, durability, and cost-efficiency of a project. By carefully evaluating each aspect, manufacturers can create components that meet precise mechanical requirements while ensuring reliability over time. The decision-making process should not be rushed, as the long-term performance of composite structures depends heavily on selecting the right UD fabric from the start.

Define Application Requirements

The first step in choosing the right Carbon UD fabric is to clearly define the application requirements. Understanding the type of load and the direction in which it will be applied is essential. For example, some components primarily experience tensile forces, while others may undergo bending, compression, or torsion. Carbon UD fabric excels when loads are predictable and concentrated along a specific axis, making it ideal for applications like aerospace spars, automotive chassis reinforcements, sporting equipment, and marine structures.

Beyond load type, consider the expected lifespan of the part and the conditions in which it will operate. Outdoor or industrial applications may require resistance to moisture, UV exposure, chemical corrosion, or fluctuating temperatures. Additionally, the desired service life will influence the choice of both fiber grade and resin system, as well as the number of UD layers required. Specifying precise performance requirements early helps narrow down material options, reduces the risk of over- or under-engineering, and ensures that the final composite will perform reliably throughout its intended service period.

Another important aspect is the component’s geometry and manufacturing method. Complex curves, sharp corners, or intricate molds may require fabrics with better drapability, while simpler shapes can utilize heavier UD fabrics with higher fiber content. Early consideration of these factors streamlines the manufacturing process and reduces waste.

Fiber Grade and Modulus Selection

Carbon UD fabric is available in a range of fiber grades, each offering unique mechanical properties. Two critical parameters to consider are modulus and strength. Standard modulus fibers provide excellent strength at a lower cost and are suitable for general structural applications. High modulus fibers, on the other hand, offer exceptional stiffness, making them ideal for precision aerospace parts, high-performance sports equipment, or industrial machinery where minimal deflection is crucial.

High-strength fibers focus on tensile performance, allowing designers to resist greater loads without increasing thickness or weight. High-stiffness fibers prioritize rigidity, which is important in components requiring minimal deformation under load. Engineers can strategically combine multiple UD layers of different fiber grades to optimize both strength and stiffness in the final laminate. For example, the outer layers might use high-strength fibers to resist surface stress, while the core layers employ high-modulus fibers to maintain overall rigidity.

When selecting a fiber grade, designers should also consider fatigue resistance. High-performance components often experience repeated loading, and the right UD fabric can significantly extend the part’s service life. By understanding the mechanical behavior of various fiber grades, engineers can design composites that meet both static and dynamic load requirements.

Resin System Compatibility

Choosing the appropriate resin system for Carbon UD fabric is equally important. Thermosetting resins such as epoxy, polyester, and phenolic are widely used because they provide excellent adhesion, chemical resistance, and dimensional stability. Epoxy resins, in particular, are preferred for high-performance applications due to their superior mechanical properties, strong fiber bonding, and durability.

Thermoplastic resins offer benefits in specific applications, such as high impact resistance, rapid processing, or recyclability. For example, thermoplastic-based UD composites are increasingly used in automotive panels that require fast cycle times for mass production. The resin system also influences environmental resistance, thermal stability, and the composite’s ability to withstand long-term loading. Ensuring compatibility between the Carbon UD fabric and the chosen resin is essential to achieve uniform stress distribution and prevent delamination or matrix cracking under load.

The curing process is another critical factor. Thermosetting resins require controlled temperature and pressure during curing to optimize fiber-matrix bonding. In contrast, thermoplastic UD fabrics can be processed using heating and consolidation techniques without chemical curing. Understanding these differences helps engineers select a resin system that aligns with both the material properties and the manufacturing capabilities available.

Environmental and Chemical Resistance

Carbon UD fabric is often deployed in demanding environments, making environmental and chemical resistance a crucial consideration. Exposure to UV light, moisture, salt spray, and chemical agents can degrade the resin matrix, potentially compromising mechanical performance. Selecting Carbon UD fabric combined with a compatible resin ensures long-term durability.

For marine applications, resistance to saltwater and corrosion is critical. Industrial environments may require protection against acids, alkalis, or solvents. Additionally, high-temperature applications demand UD fabrics that maintain stiffness and strength even when exposed to elevated heat. By matching the appropriate fiber grade and resin system to environmental challenges, engineers can achieve reliable performance while minimizing maintenance and extending service life.

Fabric Weight and Thickness Considerations

The weight and thickness of Carbon UD fabric, typically measured in grams per square meter (GSM), directly impact the composite’s mechanical properties. Heavier fabrics provide more fiber content per layer, increasing strength and stiffness, but may reduce flexibility and drapability. Lighter fabrics are easier to conform to complex shapes but may require additional layers to achieve the same mechanical performance.

Engineers must also consider how many plies will be stacked and the resulting laminate thickness. The combination of fabric weight, ply orientation, and layer count determines the final strength, stiffness, and overall weight of the composite. Optimizing these parameters ensures efficient material use while meeting design specifications. For instance, aerospace components often use a combination of lighter UD fabrics for intricate shapes and heavier fabrics in flat or less complex areas to balance manufacturability and performance.

Cost-Performance Balance

Cost is always a factor when choosing Carbon UD fabric. High-performance fibers with advanced resin systems deliver superior mechanical properties but can be expensive. Standard-grade fibers may be more economical but might not meet performance requirements for critical applications.

A careful cost-performance analysis allows engineers to choose the most efficient material without overspending. For example, using high-modulus fibers only in critical load-bearing layers and standard fibers elsewhere can optimize both cost and performance. Considering the total lifecycle cost, including maintenance and potential replacements, is also essential. A slightly more expensive material with longer service life can result in significant savings over time.

Conclusion

Carbon UD fabric is a high-performance, versatile material that delivers outstanding strength, stiffness, and durability when selected and applied correctly. Making informed decisions about fiber grade, resin compatibility, environmental resistance, fabric weight, and supplier reliability is essential to unlock its full potential. Proper selection ensures lightweight, strong, and long-lasting composite components, while minimizing waste, cost, and manufacturing challenges. For applications in aerospace, automotive, industrial equipment, or structural reinforcement, using the right Carbon UD fabric is critical for achieving cost-effective, high-performance results.

For those seeking premium-quality Carbon UD fabric and expert guidance on material selection and application, Jiahe Taizhou Glass Fiber Co., Ltd. offers reliable solutions and technical support. Partnering with Jiahe ensures access to high-quality fabrics, professional advice, and consistent supply, helping engineers and manufacturers create optimized, durable composite structures that meet demanding performance requirements. Contact Jiahe Taizhou Glass Fiber Co., Ltd. today to explore tailored Carbon UD fabric solutions for your projects.